The rapid global shift toward minimally invasive surgical procedures, advanced procedure-specific robots, and rapidly developing healthcare infrastructure is expected to lead to increasing demand for surgical robots. However, due to the complexity of engineering required to create these devices, many surgical robotics companies will encounter challenges that slow development. Those challenges may require tradeoffs between speed and quality, but that doesn’t have to be the case. Our team at 219 Design has the engineering skills, experience, and expertise to keep our surgical robotics clients’ development on schedule without sacrificing quality.

What Have We Done?

219 Design has worked with Intuitive Surgical, Auris Health, Levita Magnetics, Neocis, and other confidential clients on projects that leverage our interdisciplinary skill set and cross-industry experience. We understand your need to make progress on multiple, complex, undefined fronts simultaneously. When facing the urgency to make real developmental progress with internal and external pressures, an honest and trustworthy development partner can make all the difference.

High Fidelity R&D Prototyping

Companies often ask us to assist with R&D to explore a variety of concepts or prove out new technologies. This often leads to a need for fully functional, high quality prototypes. In the area of surgical robotics, we have…

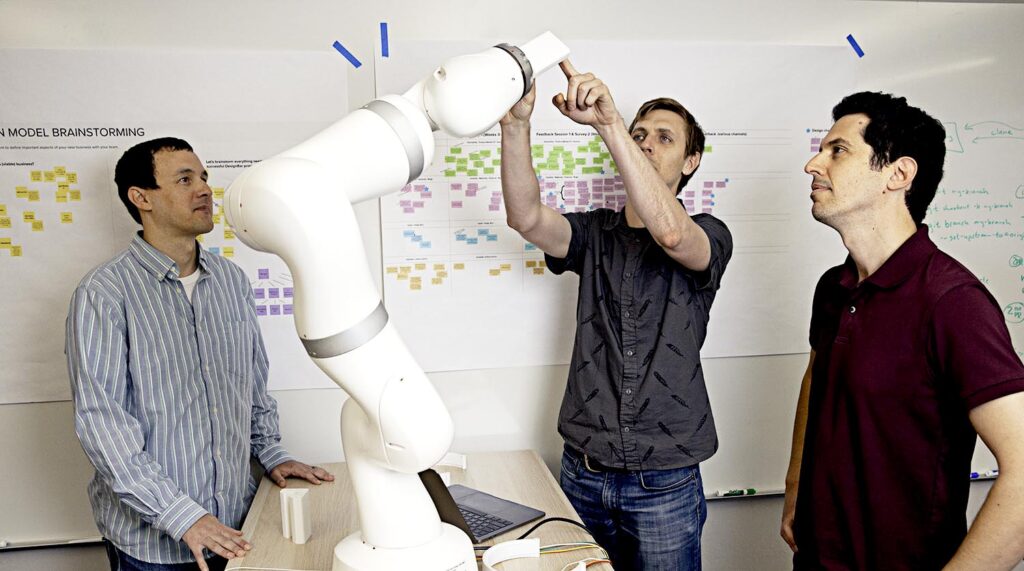

- programmed a collaborative robot arm to enable early-stage clinical trials of a novel robotic surgery platform

- performed experimental R&D projects to automate workflow

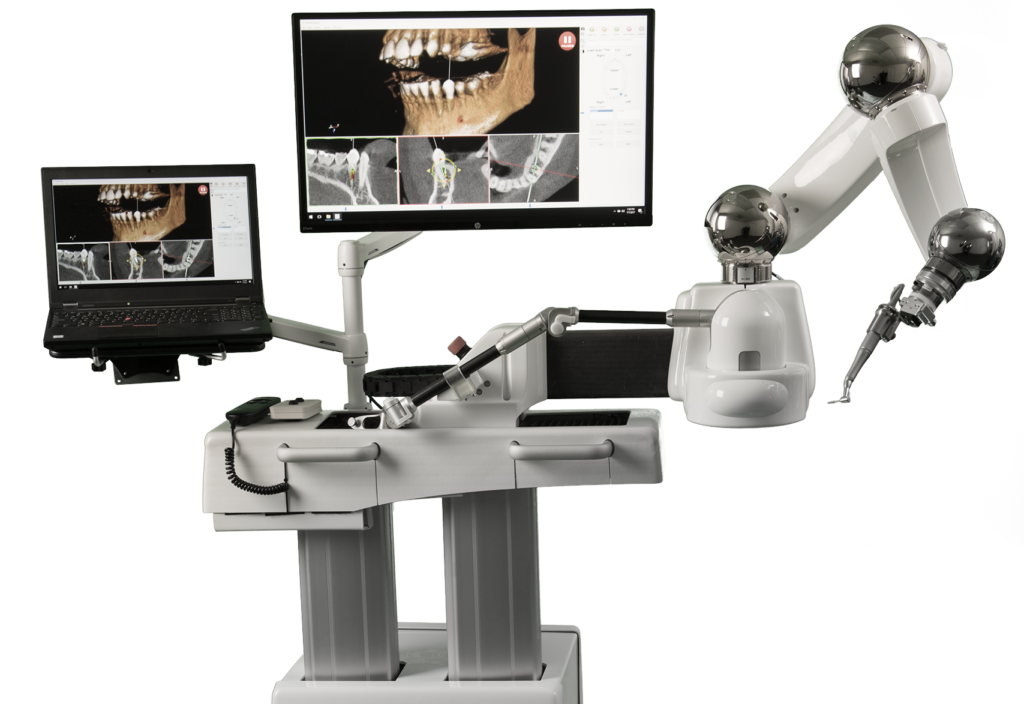

- developed a mobile cart for a surgical robot platform

- designed and developed new ways for the operator to interact with the surgical robot, including hand and foot controllers tracked in 3D space

Graphical User Interfaces

We have deep GUI experience across industries including medical devices and consumer products. Specifically in surgical robotics, we have…

- designed, architected, and implemented production GUI software for a laparoscopic surgical robot

- developed a GUI to select and run simulation exercises for a surgical robot

- developed a touchscreen-based GUI for the setup and cleanup of a custom robotic cart

- developed and administered A/B tests to determine the most effective interface for surgeons and support staff to interact with a robotic system

- rapidly developed interactive desktop and tablet-based prototypes to demonstrate and down-select UI design concepts

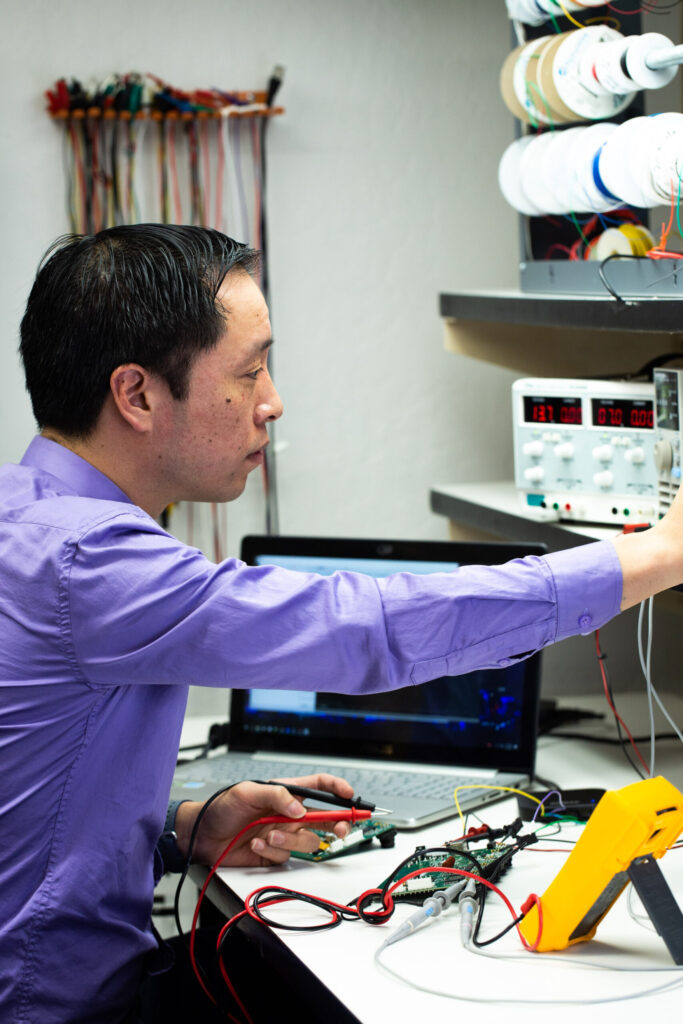

Production Embedded Design

Our firmware and software team develops and ships production code for a wide variety of applications in different industries. Specifically for surgical robotics, we have…

- developed motor control software for a positionable surgeon chair

- written firmware to format raw video frames coming from an endoscope to a standard video output displayed to the user

- developed firmware to communicate settings selected by the robot operator to peripheral devices in the system

- revised several aspects of a robotic system’s electronics design for improved EMC, functionality, higher performance and to be more development-friendly

- overhauled several circuit boards and updated the interconnect strategy to improve reliability and testability

- provided EMC support to resolve issues identified in testing

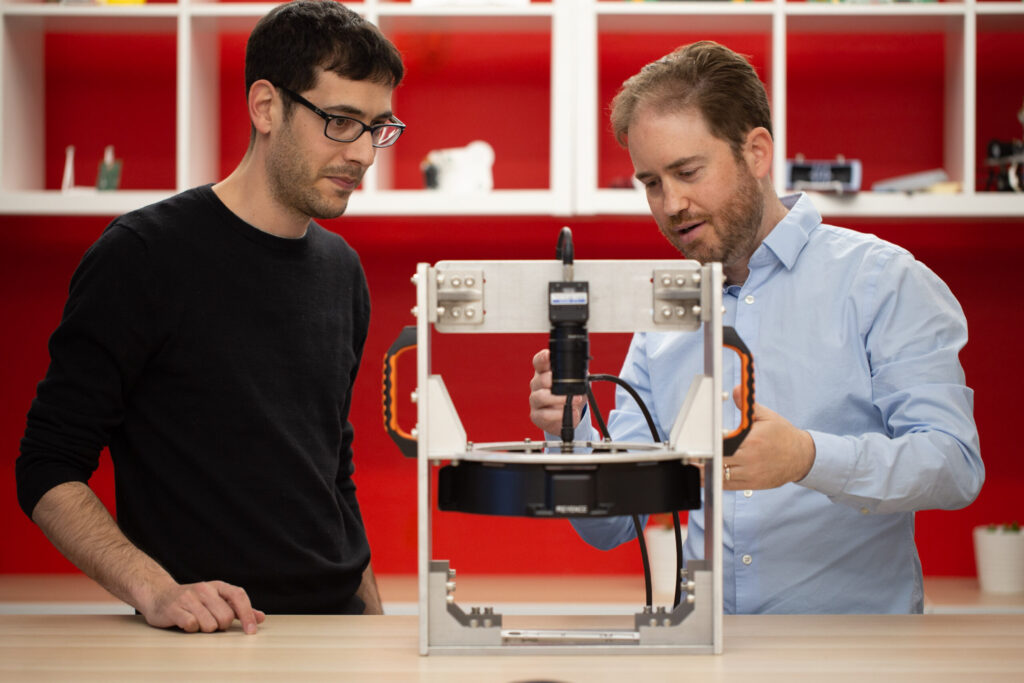

Diagnostic Software and Testing

We have worked with a number of clients to develop diagnostic software for testing. For surgical robotics clients, we have…

- written a collection of executables and scripts to facilitate the integration and automation of 1st and 3rd party sensors for positional tracking and streamlining experiments

- developed a diagnostic software test suite involving test scripts and benchmarking of the system

- helped our client’s software team develop a virtual version of the system to facilitate testing in simulation

- developed test fixtures to validate the performance of sub-assemblies in production

Data Analysis

219 Design works with a variety of teams to analyze data and improve performance. For surgical robotics clients, we have…

- built an in-house data analysis tool to process 10s of gigabytes of data at a time and allow control engineers to visualize robot performance

- designed and developed various graphical tools to analyze and visualize data collected during surgical robot testing

- analyzed very large data sets in order to graph, visualize, and assess accuracy of position and orientation of robot arm with different tools and movement patterns using Python scripts

- benchmarked and analyzed performance how a system was tracking its 3D tracked user device based on diagnostic data collected from a robotic system

Achieve Your Goals

Most surgical robotics companies will encounter challenges during development. If that has been your experience, 219 Design can help. Whether it’s 3D visualization, physical and graphical user interface design, data analysis, system testing, imaging processing, or simulation, surgical robotic development requires a lot of specialized knowledge. Our multidisciplinary team of engineers have worked with clients in industries including surgical robotics, consumer electronics, and medical devices since 2004. We leverage that experience to solve new problems every day. It’s that diverse knowledge base that will help you achieve your goals – even the big hairy ones.